Most of us are aware of the American technical giant, Apple and the high market value and reputation they have generated over the years. Among its many popular products, Apple iPhone have contributed hugely to company’s revenue.

Some years back,

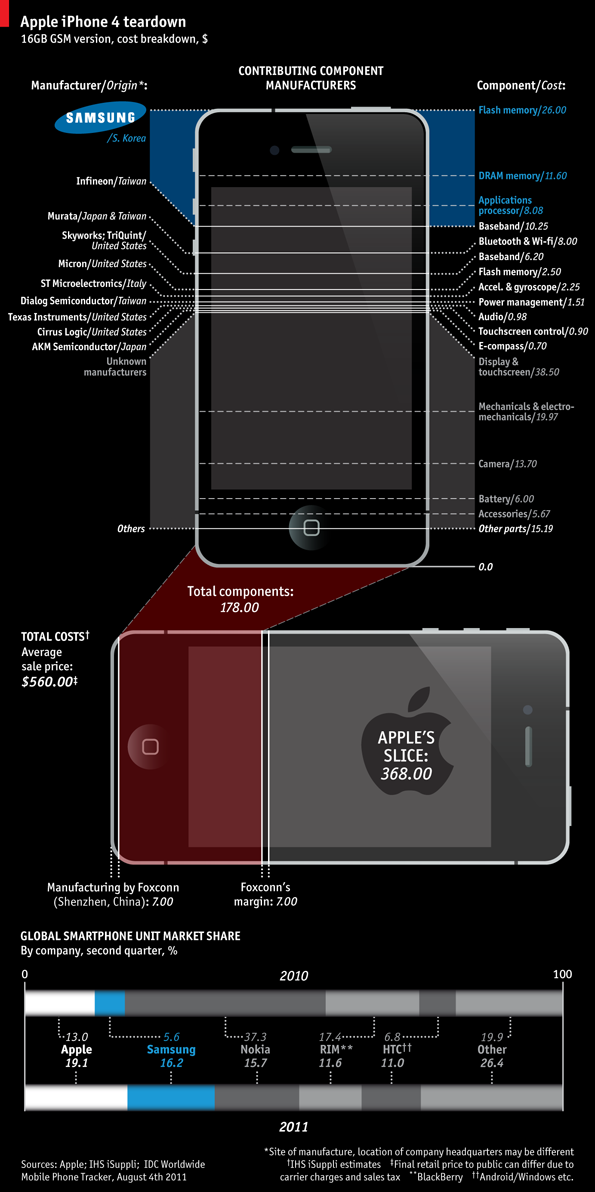

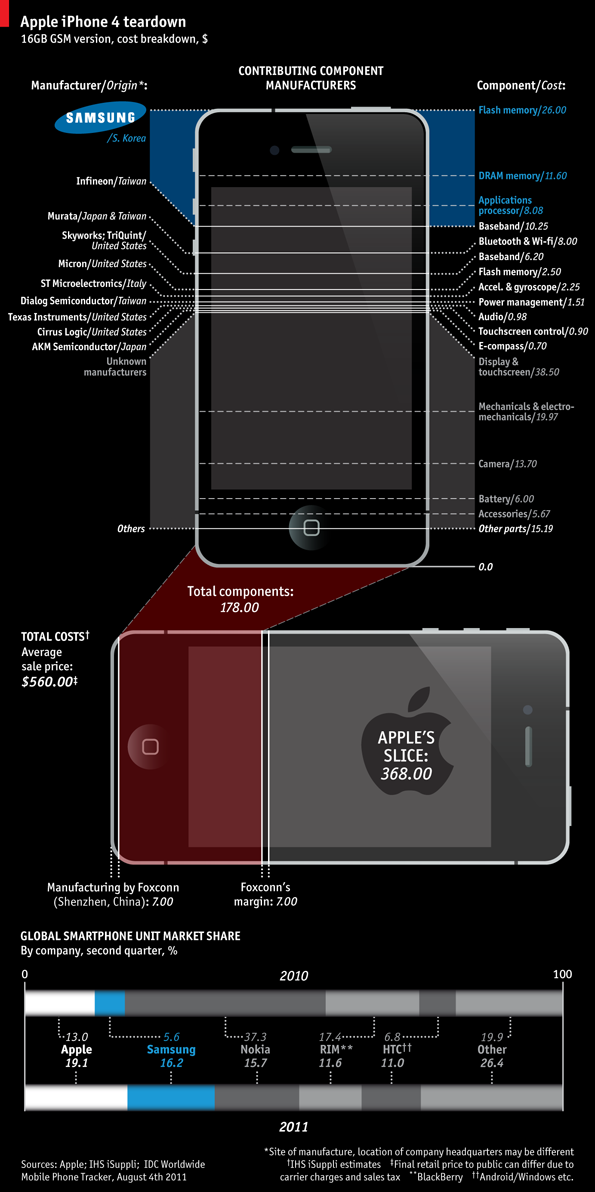

www.economist.com published an article explaining manufacturer’s wise contribution of making a famous apple product, the Apple iPhone 4. If you will look closely in the graphic below, you will find names of multiple countries like Japan, Taiwan, China, etc. contributing different components for the final product. At the bottom of the image, you can observe the share of Apple in the total selling price, a whopping $368 out of sales price of $560 for an iPhone 4. This feat was possible primarily because of two reason, the high market value of brand Apple which allow them to sell their product at a premium and the global sourcing policy by Apple leveraging strength of multiple countries around the world. The second reason of Apple’s success, the strength of a sound sourcing policy has often been ignored.

Let us try to understand what kind of sourcing policy trend is prevalent in India and how it can be effectively utilized.

Before dwelling further in Sourcing policies, let us understand where it fits into a supply chain model. A typical supply chain model look like this:

It starts with planning followed by sourcing and other activities finally leading to customer. The concept seems simple. A manufacturer buys raw material, process it and then delivers the final product to customer. Common sense tells us that any manufacturer over a period of time will get to know who the supplier in market is and he can simply place his order as per demand. So what’s the need of any separate policy? Well, the Indian industry started working with this framework only, in the beginning. They did have certain rules related to purchasing of items but that was it. Most manufacturers were producing their final products as well as their components in-house and the only material requirements were some basic raw materials like iron, steel, coal, etc. in case of a manufacturing firm. However, over a period of time, especially post-independence, Indian industries started growing in terms of variety as well as scale. The new concept of economies of scale started gaining momentum. According to this principle, the cost of manufacturing an item decreases with an increasing number of items in production. However, with ever increasing product variety of products, manufacturers were finding it difficult to produce multiple products and at the same time retain cost advantage. In other words companies started shifting from traditional

vertical integration to

horizontal integration and sometimes a mix of both.

Horizontal and Vertical Integration:

According to Wikipedia

Horizontal integration is

“the process of a company increasing production of goods or services at the same part of the supply chain. A company may do this via internal expansion, acquisition or merger. The process can lead to monopoly if a company captures the vast majority of the market for that good or service” and

vertical integration is "an arrangement in which the supply chain of a company is owned by that company itself".

Have a look at the attached graphic depicting features of horizontal and vertical integration.

Deciding the sourcing policy: The Sourcing Design Matrix

Sourcing policies for items are traditionally categorized into various types based on three parameters as depicted in chart shown. The parameters are:

-Contact Duration: It is duration for which a customer and a vendor shall remain in business or in general till the time product is delivered.

-Specificity: It means how many substitutes are available for the product.-

-Transaction cost: The cost incurred in executing the contract.

Understanding the major policy types in Sourcing:

- Request for proposal: More commonly known as RFP, this type of policy is used for purchasing items that are more complex and expensive and where there may be number of potential vendors. This sourcing policy is very popular in Indian context particularly with Indian government and PSUs. Let us try to understand this process in details.

As it is visible, the transaction cost will be high as the whole process is cost intensive. In some cases when less vendors available for given product, companies may decide to open tender by publishing RFP in newspapers. This is also a very prevalent method in India to increase the number of competitors and reduce the price during reverse auction/negotiations. These types of contracts are usually on one time basis and hence have lower contract duration. As number of vendors are high, specificity is low.

Strategic Alliances: This is another very prevalent sourcing policy in Indian context. Buyers who have dealt with suppliers in the past or on-boarded new suppliers using RFP methods may decide to have an extended contract thereby uncertainty in future primarily on account of price and sometime to counter uncertainty of supply. Since this sourcing policy deal with single vendor, specificity is high. Also, the transaction costs are higher as the process involves lot of paperwork and other technicalities.

Vendor Managed Inventory: Also known as VMI, here customer actually allow the supplier to manage the inventory policy of an item or group of items. The supplier is given the basic data about company requirements in future and is also given the freedom to decide the replenishment schedule. This method is evolved after JIT wherein inventory is minimized by reducing waste. In this case the waste is delayed in supply and excess inventory. This sourcing policy provides the vendor with better coordination and thus reducing the variability in demand, popularly known as “Bullwhip effect”. This methodology is particularly popular in the automobile sector where the numbers of parts are huge and thus maintaining an optimum level of inventory is better managed by multiple VMI systems rather than the automobile company.

Conclusion:

The list of sourcing policies mentioned above is not exhaustive. There are some other types as mentioned in design matrix and possibly more with some variations of existing ones. However it can be concluded that in the past few decades sourcing policy has taken a pivotal role in an organization policy design. With a fast paced competitive environment like today, most companies are looking for an edge over their competitors. Sometime it is brand driven while some time, it may be cost driven. Apple managed to do both and look how successful they become. Clearly an effective sourcing policy is the “edge” organization need to make the difference they wanted.

References:

http://www.economist.com/blogs/dailychart/2011/08/apple-and-samsungs-symbiotic-relationship

http://ashasmaritimenews.blogspot.in/2012/04/supply-chain-in-container.html

https://en.wikipedia.org/wiki/Vertical_integration

https://www.studyblue.com/notes/note/n/16-global-sourcing-and-procurement/deck/13243901

http://www.canstockphoto.com/strategic-alliance-concept-in-tag-cloud-10639879.html

http://resource.centerscm.org/2015/08/vendor-managed-inventory.html

www.cerasis.com

-----------

About the Author:

Vaibhav Gupta is a student of IIM Calcutta 2017 batch. He has close to 5 years of industry experience across design, procurement and project management prior to joining IIMC and has a keen interest in subject related to operation, strategy, motivation and leadership. He also has a particular interest in understanding people and helping them out along with a natural attraction towards writing and quotes.